My Work

My work is comprised of various types of production. From wheel throwing & hand building, to slip casting. Often times my work is a combination of some or all of these types of processes. I also use various forms such as plaster, stamps, stencils and lace in my work. What I actually produce depends on the time of year or what I develop. I can develop a new piece and make many of them and then move on to something else, or I may make several different types of work and bounce from form to form. Some days I do not know what I will be doing until I get to the studio and just dig in!

This was a piece that was cut from a template I have and I am centering a piece of wood on it. The clay is on a piece of sturdy foam and I will push the wood into the foam, turning the flat piece of clay into a tray or platter.

Red clay rolled out and ready to be formed.

This is a plain pumpkin plaster mold. Liquid clay is poured into the mold to form the pumpkin. Once removed, the brow was formed by pushing out the clay from inside and then cutting out a face

Here clay has been rolled out. I have a rectangular piece, a coil and a round piece. These three will form a cylindrical spooky Halloween form.

This is a perfect example of a multi process piece. The clay was rolled out into a flat piece, cut, and placed over a bowl shaped plaster bat on the wheel. It was then formed and compressed and a foot was formed with the fingers. The bowl is basically thrown upside down.

Pressing a flat piece of clay into foam to form a shape

Clay is formed around a plaster cast and shape cut around the form.

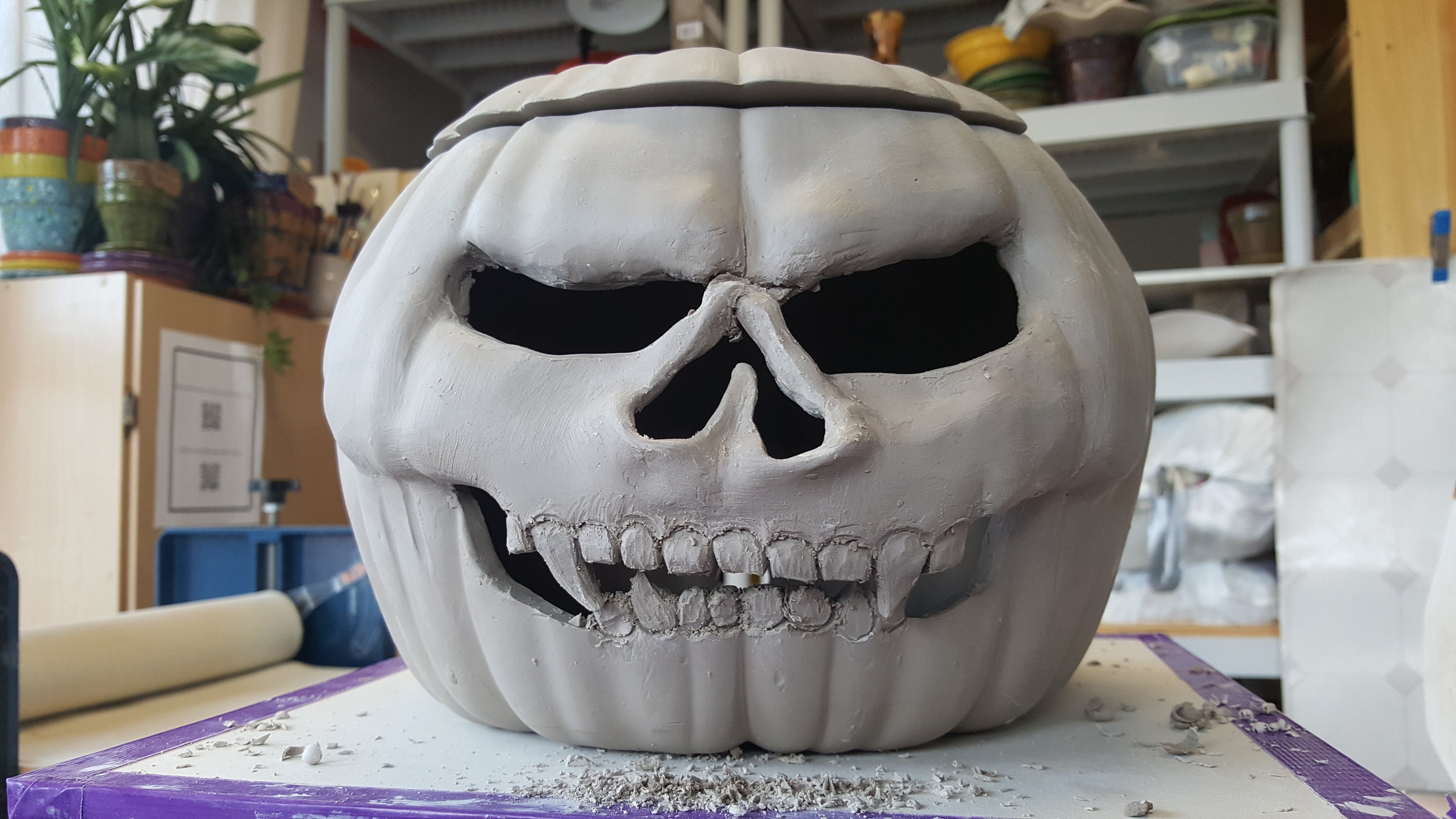

Another pumpkin. This mold is plain and is great because the faces you can make are endless!

Here the 3 pieces are being put together. The coil is placed inside at the seams to provide strength. A face is then cut out

This is another multi-process piece. The casserole is thrown on the pottery wheel and the top is thrown on the wheel with a plaster bowl shape mold using calipers to ensure its the right size to fit the casserole base. You form a handle while making the top piece.

Balancing the pressed piece before covering it with plastic to dry slowly.

The bisque fired piece ready for glazing.

A completed pumpkin.

The finished bisque fired piece, ready for glazing.